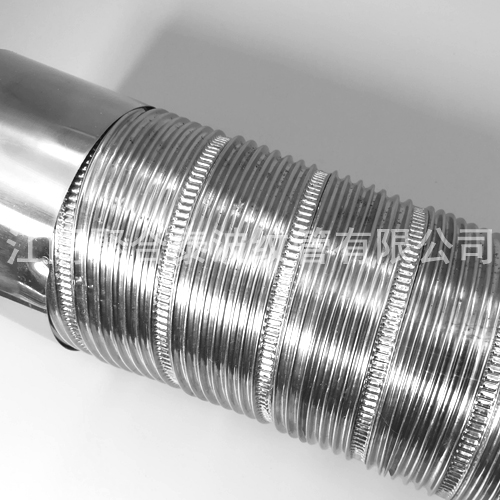

Metal corrugated pipe and fin cooler, the application of bellows in internal combustion engine cooling core in petrol and diesel engine cooler casing or between two tube plate installation of 1-1000 root with intermittent convex-concave shape metal corrugated pipe, by adopting the method of expanding method, the welding should be fixed on the tube plate at one end, which changes the flow of the cooling medium, to improve the heat transfer coefficient, increase the heat transfer efficiency, technology and practical, low cost, reliable performance, high heat transfer efficiency, scale, long life, small thermal stress.

According to the state of the hose when used, refer to the correct use and installation method of the metal hose and the better length of the hose in settlement compensation. Calculate the length of various motion states of the hose, minimize the bending times of the hose, minimize the bending radius and other factors, select the correct length of the hose and install it correctly.

Notes for several bellows:

1、pressure according to the actual working pressure of the hose, and then query the nominal size of the corrugated pressure gauge, decide whether to use stainless steel mesh sleeve type.

2、Nominal size of hose, choose connection type (mainly flange connection, thread connection, quick connection) and size, length of hose.

3、the temperature of the working environment temperature of the medium in the hose, high temperature, according to the metal bellows high temperature working pressure temperature correction coefficient, determine the temperature after the correction of the pressure, to determine the selection of the correct pressure level.

4、According to the corrosion resistance parameter table of the hose material, the material of each part of the hose should be determined.

5、Vacuum hose is mainly used in monocrystalline silicon production to achieve negative vacuum.

The bellows used in steel belt are steel bellows, also known as steel belt reinforced polyethylene spiral bellows. It is a kind of winding wall tube with high density polyethylene (PE) as matrix (inner and outer layer) and surface coated and bonded resin steel strip. The tube wall structure is composed of three layers: the inner layer is a continuous solid wall PE inner tube, and the outer layer of the inner tube is wound with annular corrugated steel belt reinforcement, and the outer layer of polyethylene is compounded in the outer layer of corrugated steel belt reinforcement, so as to compound into an integral spiral bellows.